Here's how to turn some junk parts into a good 1-1/2 x 30 inch belt grinder attachment for your old Craftsman block motor grinder.

A few years ago I replaced the timing belt, water pump, and idler pulleys on my Isuzu Rodeo. I kept the pieces in my junk box and this week I decided to make a belt grinder attachment out of them. Any car that has similar setups can yield these components --

Here are the pieces that I used for this project -- an idler pulley and a water pump pulley

I decided to use the water pump pulley as the drive side that attached to the bench grinder shaft. The water pump pulley edges and sides need to be turned flush -- as in the following pic. Other pulleys may not require this, but this one needed to be modified in this manner to fit the bench grinder shaft.

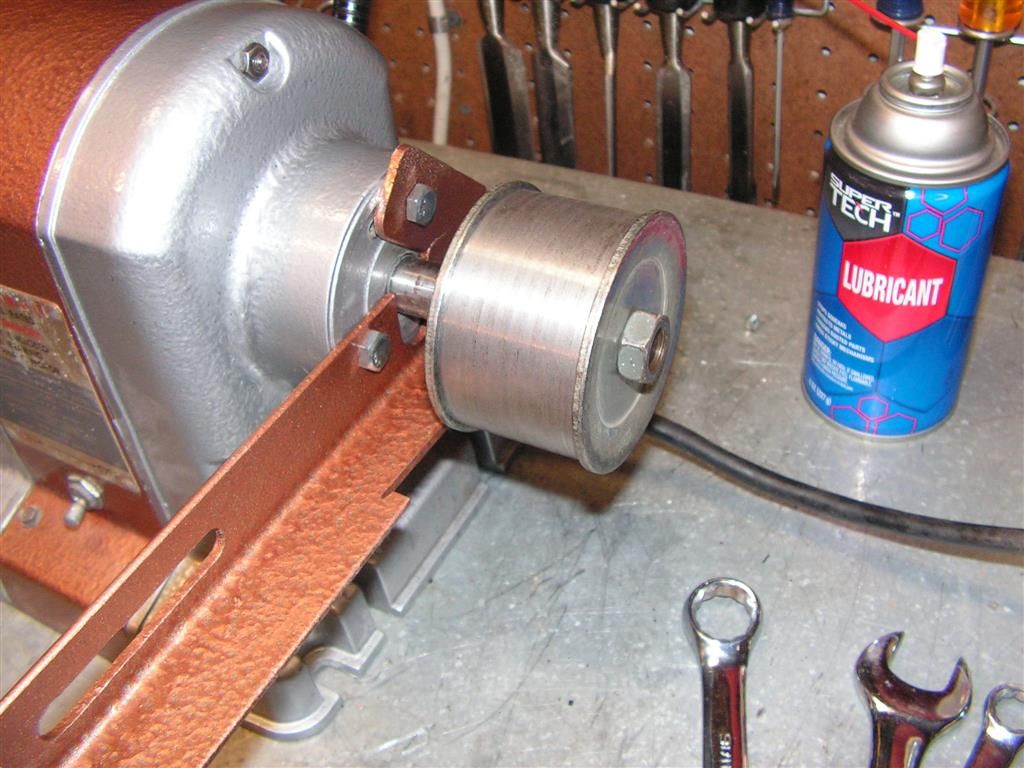

Here is the water pump pulley temporarily mounted on the grinder using the large OEM washers that came with the grinder to hold the pulley in place. The Craftsman OEM washers are just a bit larger than the pulley and will act as guides for the 1-1/2" x 30" grinding belt

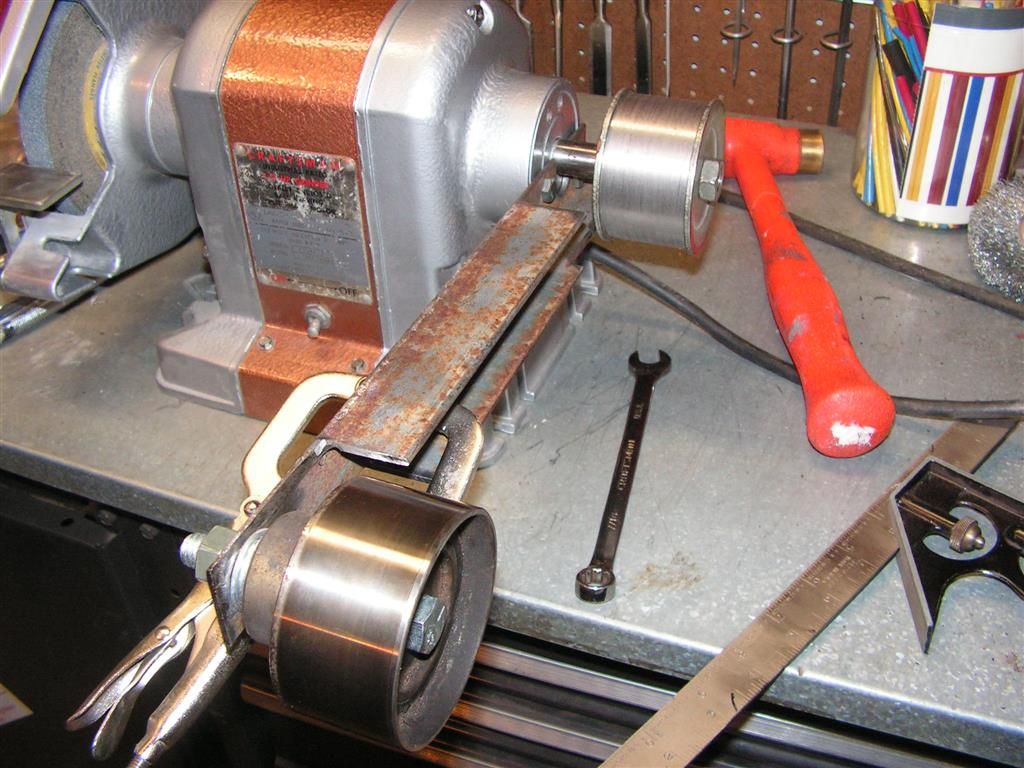

The old idler pulley is supported by a large bearing and is therefore very steady. This pulley will become the driven grinder wheel. Here I have the machined water pump pulley and the idler pulley mounted to a piece of 1-1/2 angle iron.

Next I cut another piece of 1-1/2" angle iron to make the adjustable sliding arm that will serve as the body of the attachment as well as the belt tension mechanism.

The only other big piece that is needed is a belt/tool rest which will allow straight sanding over the top of the sliding arm. This one is fabricated out of 18 ga sheet metal.

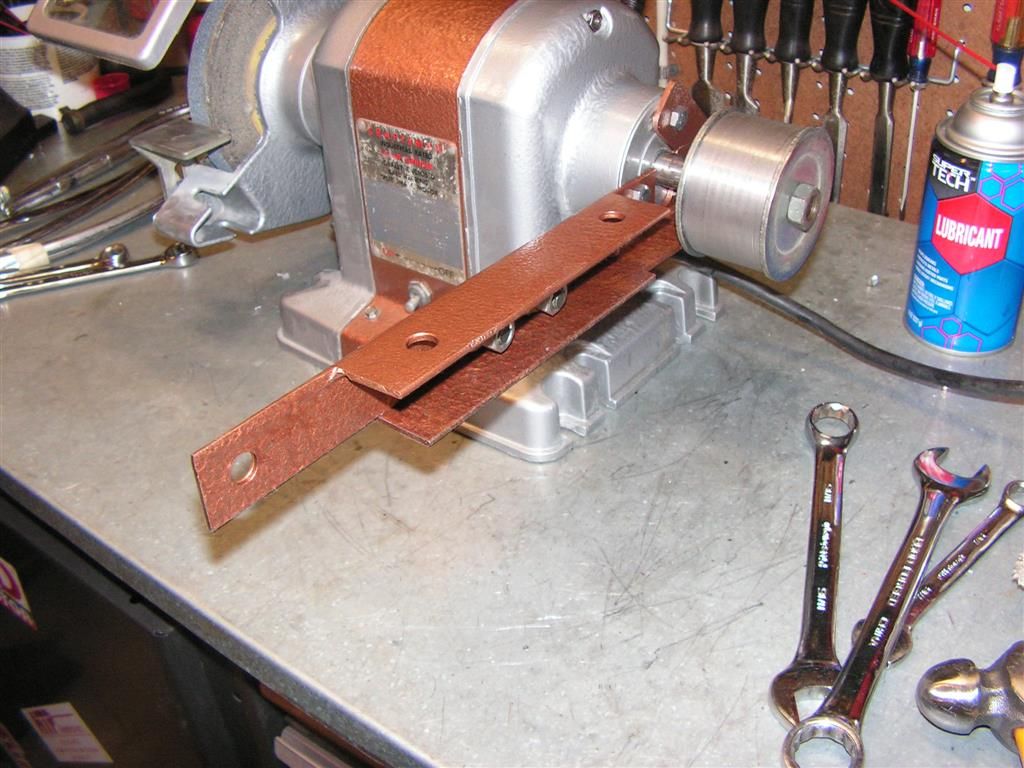

The parts are mocked up to check fit and placement, and I used the three existing 1/4" grinder cover mounting holes on the grinder body to mount the angle iron frame. The frame needed a bit of modification to clear the grinder shaft. I used a 1/2" drill and carbide burr to make the clearance for the shaft.

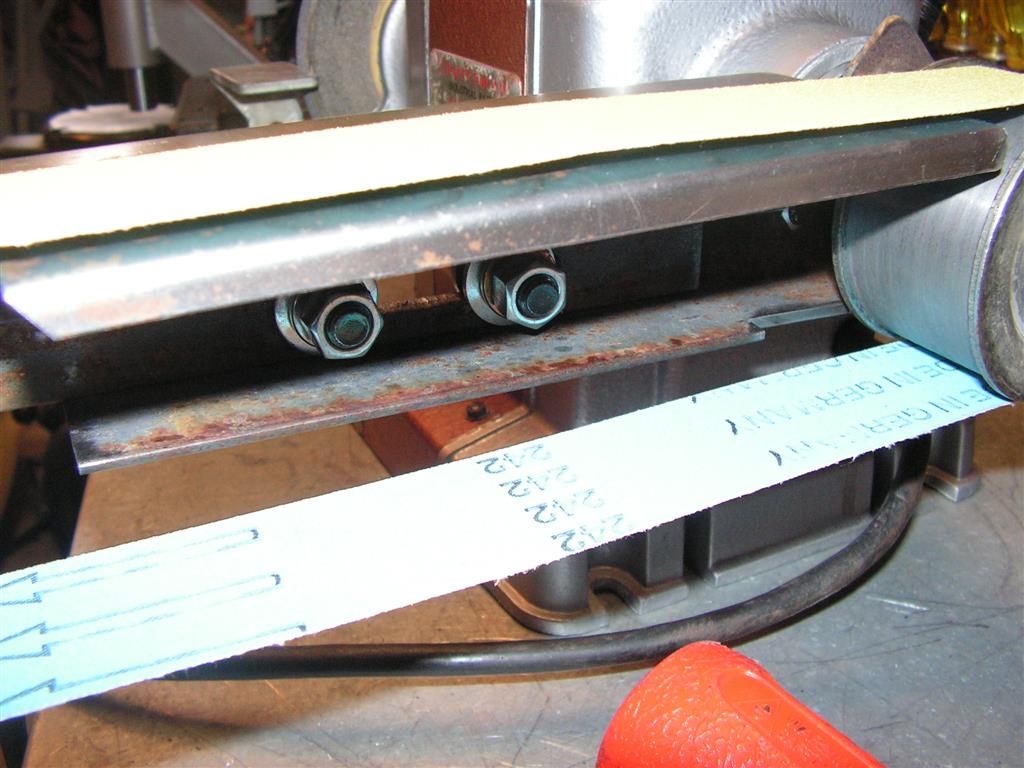

Here are the two angle iron pieces with slots down the center to make the belt tension adjustment.

The final mod was to the machined drive pulley (the former water pump pulley). I bored the hole just larger than the bench grinder shaft to press fit a spare wire wheel bushing into the opening. These bushings come with all new wire wheels and it will make this pulley run nice and true.

Next, I welded two 1/2 bolts to the bottom of the belt/tool rest so that I could mount it on the frame and also provide adjustment for belt clearance.

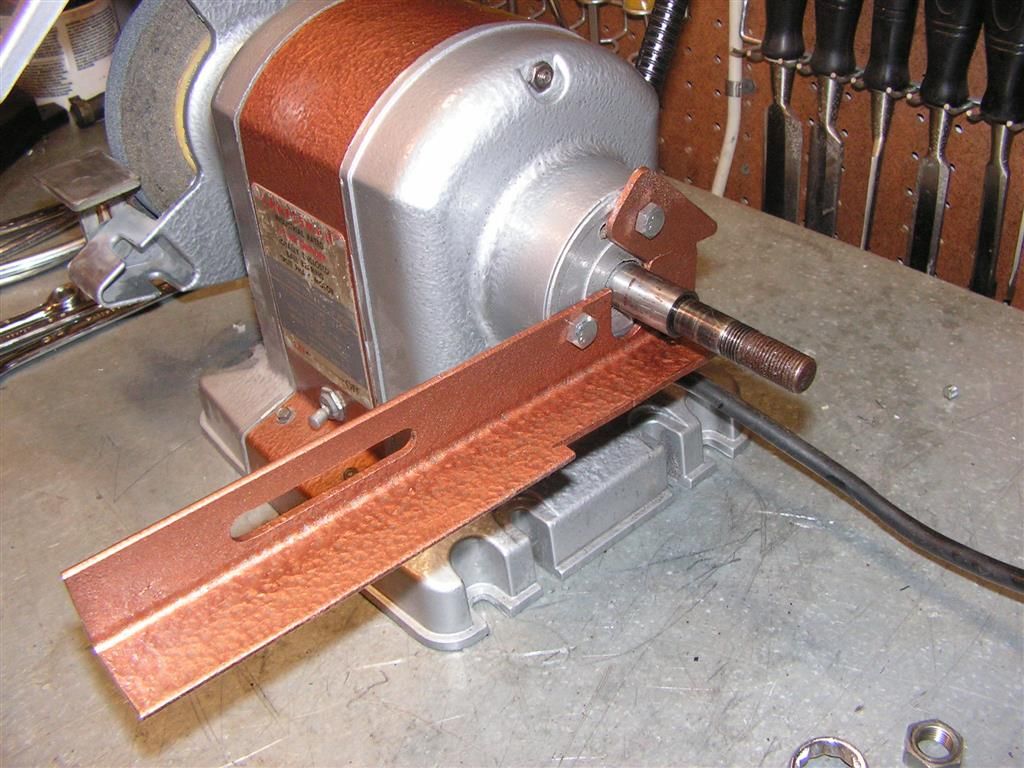

After final mock up, all the components were sanded and painted with Rustoleum Hammered paint and then assembled

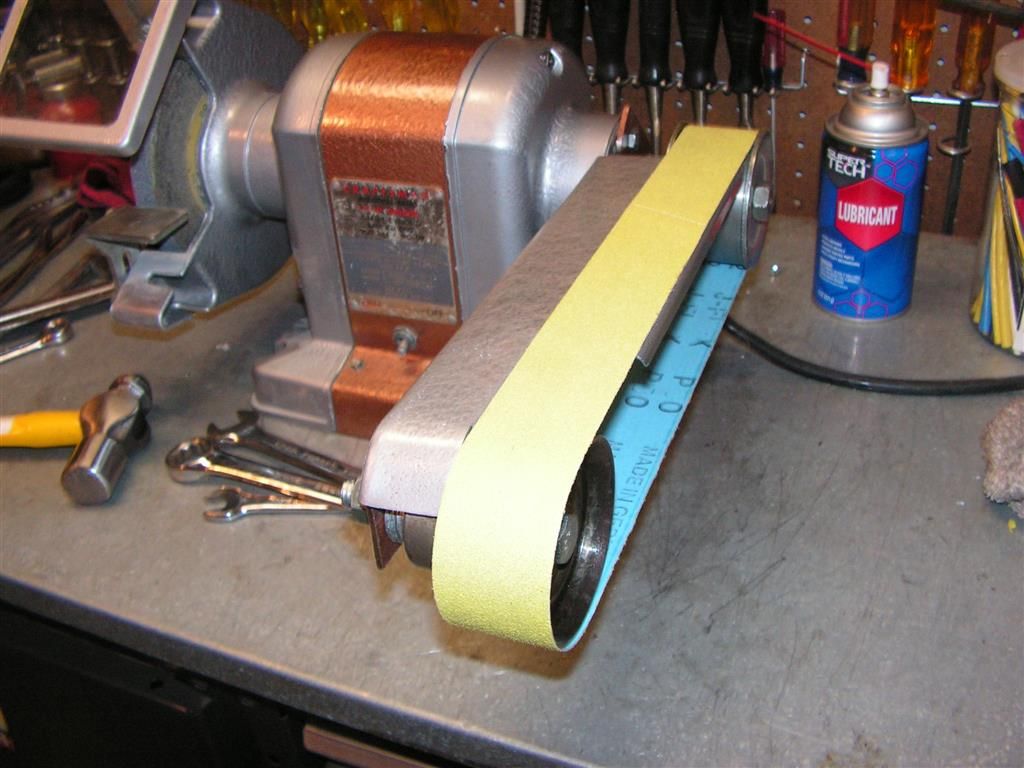

Here is the final assembly --

The main frame piece is attached to the grinder body

Then the drive pulley (former water pump pulley) is attached to the shaft.

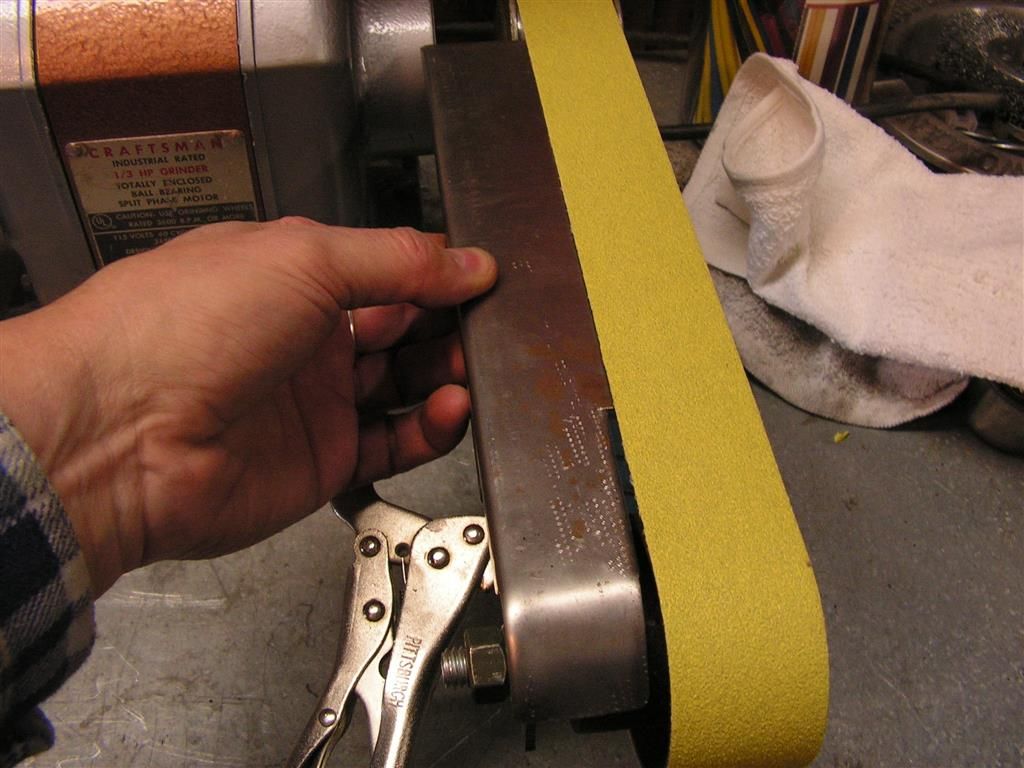

Next comes the other half of the frame with the front wheel attached (the old timing belt idler) as well as the belt/tool rest attachment -- this entire assembly will slide back and forth to make belt installs simple and easy

The belt/tool rest is adjusted to just touch the underside of the moving belt, and then it's locked in place.

We'll call this job done -- the good thing is that since the rear drive pulley has the large washer lips on each side to guide the belt, there is very little chance of a tracking error on the front pulley -- this thing runs true!

For less than few dollars in paint, hardware, and a 60 grit 1-1/2 x 30" grinding belt, this grinder attachment works just as well as the commercial $100+ units -- and this one is not made out of cheap stamped steel.

Hope some of you will try this fix yourself -- a high speed belt grinder is quite handy.

Good luck!