I love these things and owned some over the years, but unfortunately I sold or traded all of them over the years. I got reintroduced to these fine grinders way back when there was a now defunct site called the Garage Hangout, and I couldn't wait to get my hands on some of these fine old workhorses.

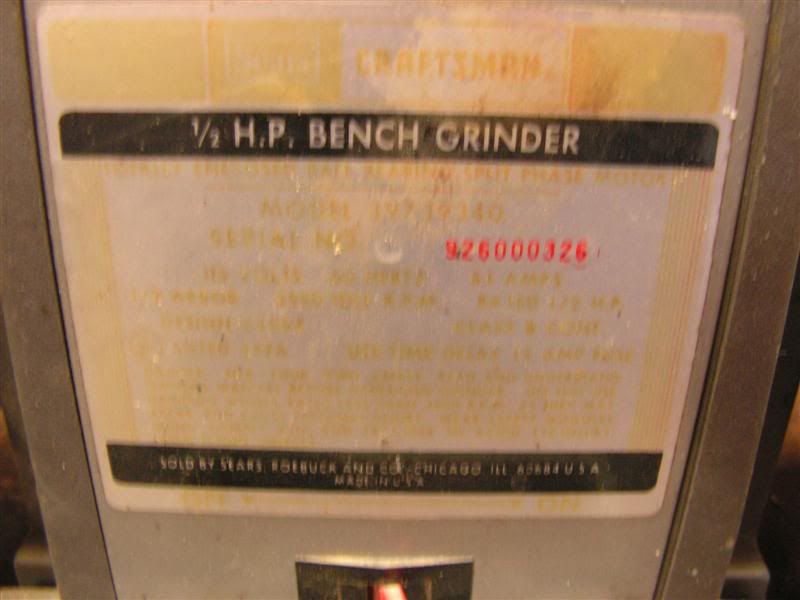

Picked it up on ebay for a song because it was listed as DOA. The venerable "Block Motor" grinder was one of Sears' best power tools ever. Knowing that these things are bullet proof, I bet on the fact that it was a faulty connection and not a bad motor -- it was a good bet.

Turns out it was a bad switch that had fried when a hot wire that was feeding it shorted out. No big deal!!! th-bounce

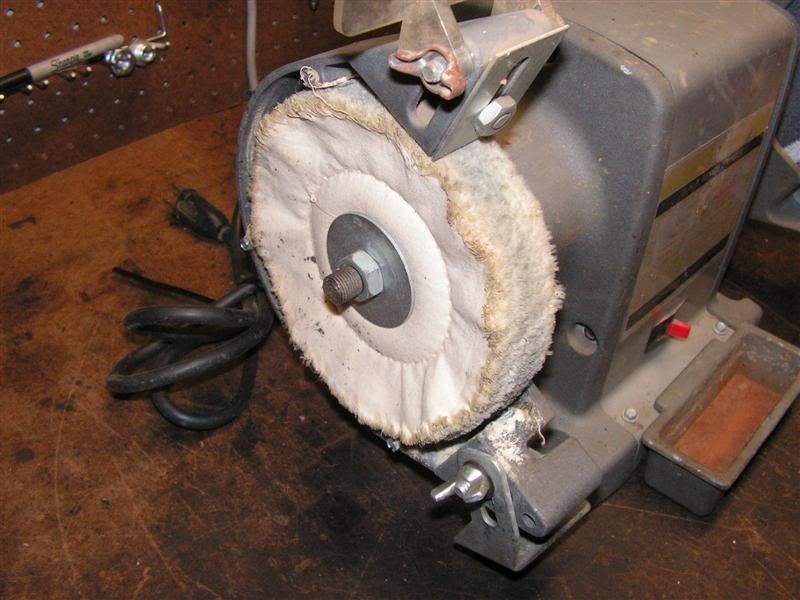

Previous owner stuffed a very thick buffing pad on the left side and it must have frayed to all get out when he turned it on because the pad threads are caught in everything.

Right side is the OEM 6 inch medium grit wheel and it still rings good when "pinged".

Bypassed the faulty switch and she started right up -- smooth as silk.

Bad switch --

All apart and ready for some "love" --

People always want to know what makes these things so special; here's the reason.

Look at those field windings. That is some VERY thick copper wire. When compared to a modern Chinese winding, these look GIGANTIC. The imports use very thin field wire. This is what makes these "block motors" so darn powerful and long lasting.

Time to go to the store and get some hammered paint.