This was a popular thread on the other GG site and I had a hard time recreating it because the images were stored on Photobucket and some of the links were corrupted. Anyway -- here goes.

If you do any amount of painting in an enclosed space using modern urethanes and enamels, then you need a fresh air system. A respirator just won't cut it because the saturation of nasty damaging vapors is much too high in such environments and can quickly saturate the respirator charcoal cartridges. The main culprit is a compound called isocyanate -- which is among other things a main ingredient of the catalyst hardener we add to the paint.

It's a nasty compound and not easily eliminated from the body when absorbed. Hence we need to protect ourselves.

You can purchase an industrial grade fresh air system on Amazon and Zoro with a cost from about $1000 to $1800 dollars ......

https://www.zoro.com/allegro-supplied-air-system-15-psi-1helmet-9248-01/i/G5281997/feature-product?gclid=Cj0KCQjwn4ncBRCaARIsAFD5-gUUB-RrWCxEqb7M2MYgwqm6ZWHdri6QdMhbuqMfaLYTpeR7xVb2VhUaAmKaEALw_wcB

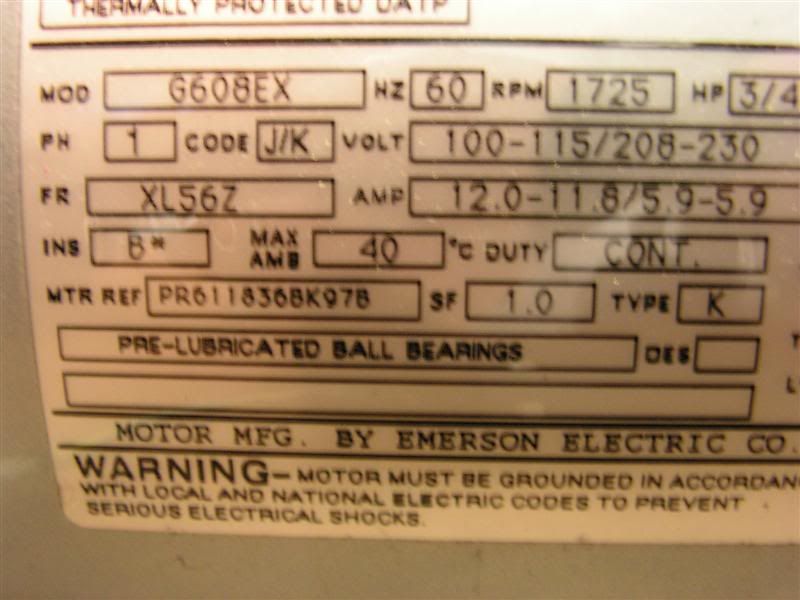

.... or you can build one yourself. Notice in the above picture -- the main component of the system is a carbon vane driven oil-less pump that is an industry standard. GAST is the premier manufacturer of these pumps and they can be used as both an air source as well as a vacuum source depending on which port you decide to hook into. These pumps are incorporated into a lot of industrial machinery, such as copiers, large printing presses, vacuum packaging machines, etc.., hence they are available on the used market such as ebay (or industrial surplus vendors) for very reduced prices.

NOTE -- find a pump that was NOT used in a biological or hazardous waste function as a vacuum pump. Caution is key here. Also, the vacuum/compressor pumps are usually less expensive with 220v motors versus the more versatile and expensive 120v versions. In any case the pump units will have to be thoroughly scrubbed and cleaned with soap and water and denatured alcohol to make them usable for breathable air.

Here's my setup -- a GAST 120v pump that I purchase about 10 years ago. I cleaned it thoroughly by simply removing the front pump cover and getting in there with a toothbrush and rags to get the residue. In most cases the residue is simply carbon dust from the pump vanes.

I added a canister filter housing and filter element to keep the carbon vane dust out of the airlines

The filter was purchased from Zoro and the housing from PKSafety (although any air-line filter cannister and cartridge would do).

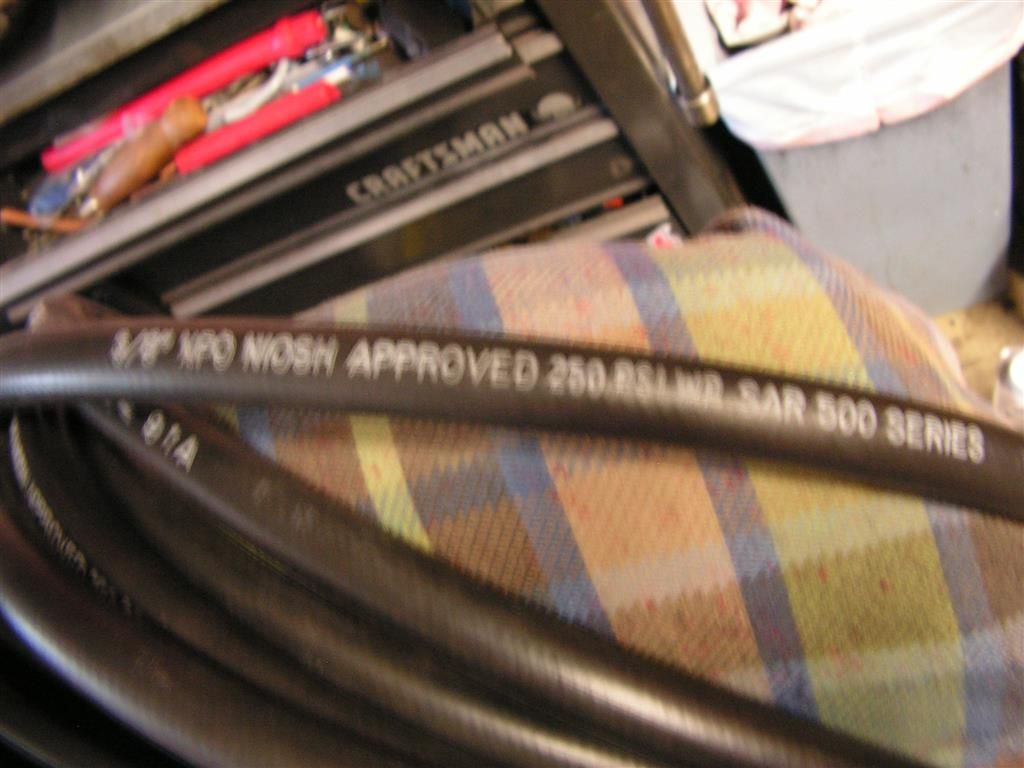

The hoses are special supplied air hoses that were purchased on ebay when they came up for sale (I didn't pay more than $20 for any of them) I have a 50ft, a 25 and a ft15 hose to make it easy to tailor a length that makes it easy to move about a paint booth. I buy any hose that is on sale and I DON'T care about proper fittings and connectors because I cut all of them off and use my own compressed air fittings to standardize on one style.

I don't use compressed air hose because it leeches toxic organic vapors and is not recommended for fresh air supplies.

For the mask I purchased a surplus full face SCBA Mask on ebay for $25 -- they are harder to find, but you can also purchase surplus Chinese pilot's masks that are half-mask design for about $30 on ebay.

Another cheap $15 option is to use a skin diver full face mask and convert (chop off the end) the snorkel tube to fit on a flexible plastic hose that runs over the top of your head.

.....it's not as comfortable as the others, but certainly cheap enough, and when attached to a new flex hose that is used with smaller shop vacs, the mask can be made to comfortably supply air.

It doesn't matter what the connector is because I epoxy one of my air fitting nipples into the mask hose end to make it fit my standardized air fitting scheme.

For convenience sake I also added a pressure regulator to the paper filter outlet as an additional screen filter to trap any residue that might make it past the first filter, and to regulate air pressure on shorter air hose runs so that the mask doesn't become too pressurized around my face and cause air gaps. I later scrapped this extra filter because it wasn't really necessary -- one good filter cartridge is sufficient.

That's it -- it works very well and just as efficient as one of those commercial $1200 units that only use a 1/4HP pump -- mine has way more capacity and in a pinch I have hooked up two masks when I team painted a trailer several years ago with a friend. We were both supplied clean fresh air. My system cost me a bit more than $100 and it's based on the same GAST pump design that the commercial systems are. It did take a few weeks to find all the pieces on ebay at reasonable cost, but the wait was rewarded with good deals.

I've built several of these systems over the past decades and (like most of the commercial systems) they were always based on the industrial GAST oil-less pumps. For a few weeks of searching the Internet and less that $200 it's worth it to protect your health if you plan on painting your car in your garage or shop. Unless you have access to a high-end professional paint booth that evacuates organic vapors almost instantly, a respirator is NOT the answer -- but the DIY fresh air system is.

I also opted to buy a pack of stick on face shield protectors to keep the original full face mask from getting full of paint and dirt. I change it every paint job for a clear view.