This was a rebuild I did after my daughter got caught up in a pile-up on I-95S

The car was in sad shape when it arrived on the rollback. It's 12 years old and we stopped carrying collision on that car after it turned 10 years and only carry liability. I was tempted to scrap it out, but I really like this model year and decided to tow the damn thing back home and start the rebuild process. What the heck -- I have tools, welding equipment, and and some time over the next month, so I will rebuild it.

This is how it arrived off the flatbed this morning -- the entire front sheetmetal and fenders were off.

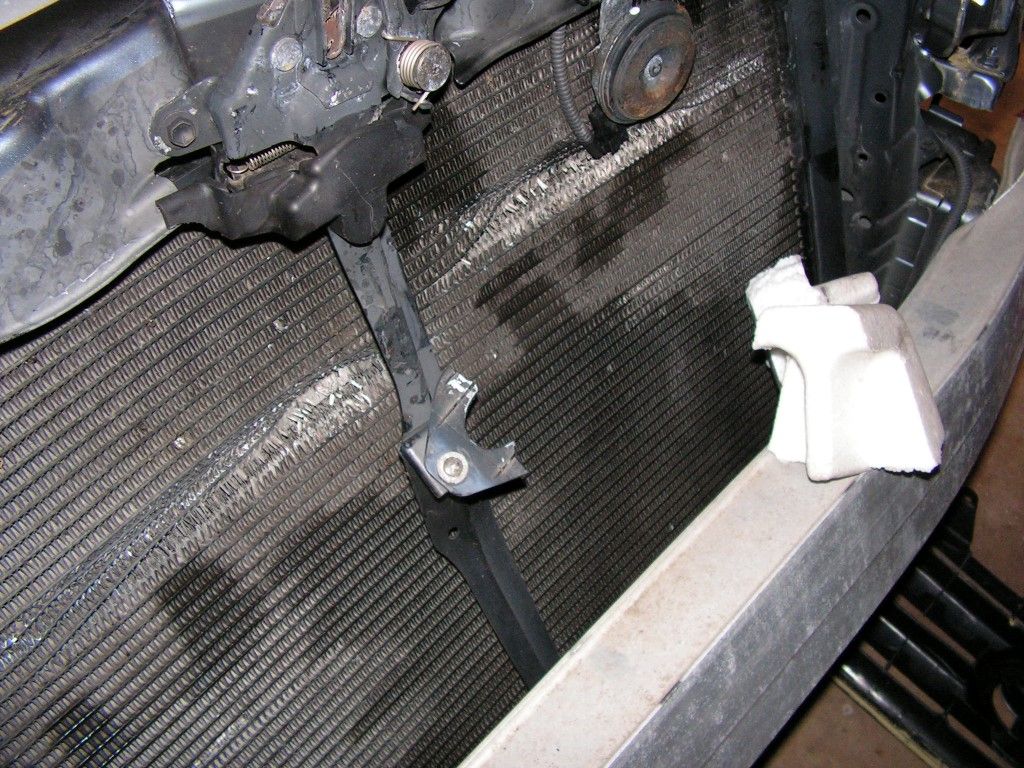

I started to strip it -- and pretty much the entire core support and ancillary pieces (radiator, condenser, lights, bumper supports), were trash.

Only thing that was intact was the "iddy-biddy" horn --

Stripping a tangled mess -- what joy!!

Headlights are toast --

The biggest issue is the reinforced frame bumper mount -- it's totally crushed. I'll have to cut this out and replace it with a new fabricated frame mount.

Radiator is toast, but surprisingly the fans are in good shape and can be reused.

Even the plastic washer bottle was spared. Which is also a surprise since it sits way in front, and right behind the bumper mount.

The core support need to have the spotwelds cut and be totally removed. My job for tomorrow is to cut all those spotwelds and remove the crushed support

Finally, at the end of the afternoon I got around to placing an order for about $1000 in new parts. I plan of replacing the parts and giving this old Highlander a new lease on life. Including this little fiasco, over the past seven years I've pretty much touched every body panel on this car with some sort of bodywork.