The noise started a few days ago and a quick check with an automotive stethoscope confirmed the fact that this PS pump was toast. The bearing noise was horrendous. In the course of a week it went from "hardly noticeable" to "screeching like a banshee". You guys all know the drill with PS pumps. The hardest part is always with the pulley.

I ordered a rebuilt pump from Rock Auto -- 2 day delivery; Rock Auto is getting better at this game.

I like to make room when I work. That's why I drained and removed the upper radiator hose and the air intake box. That leaves plenty of room to get a wrench in and out.

I clamped off the low-side fluid hose, but it still leaked a lot from when I undid the high pressure side. Oh well!!

Can't remember when I last used a 24mm wrench -- and this banjo bolt was really stuck, and needed a lot of leverage to get it to move.

Pesky 14mm pivot bolt was in a pretty tight space. It comes through from the back of the pump. Thankfully a long handled flex 1/4" ratchet made the job easier.

The rest was held in by a 14mm clamp bolt on the adjuster -- pretty straight forward.

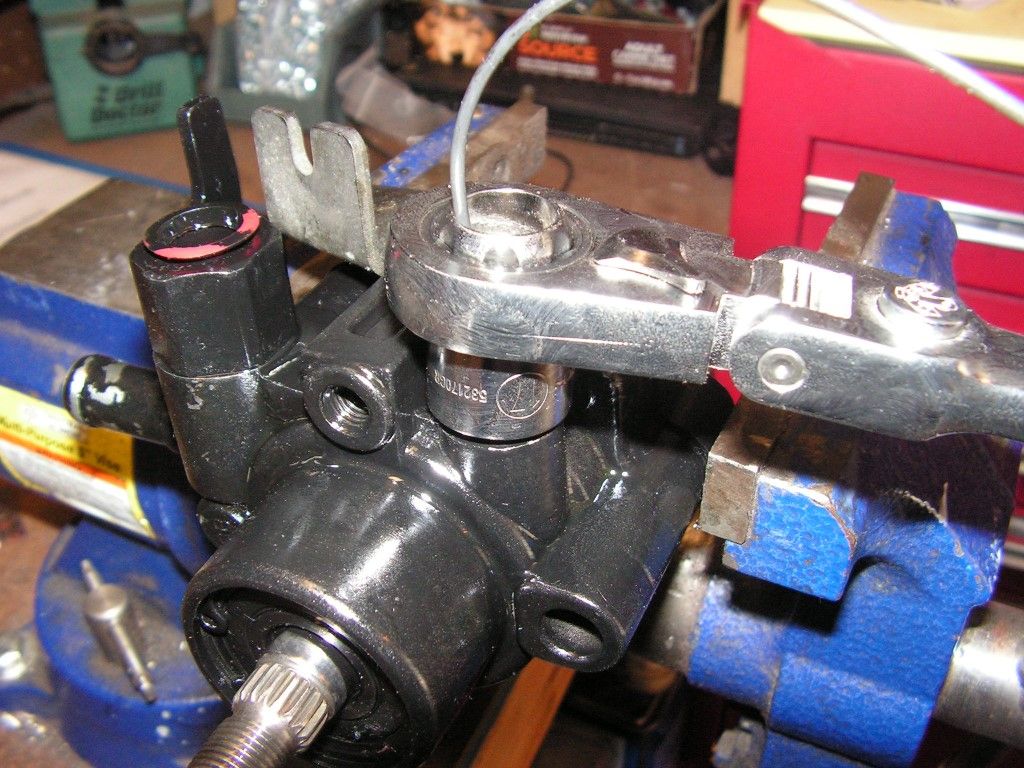

Now comes the fun part -- First thing to be switched over is the pressure sensor. It was on tight!! It has a very shallow 6pt flange and putting a lot of pressure on it with a wrench could damage it. Fortunately I do have a set of these -- an older KD Through Socket set that's open in the middle and was the perfect way to put a LOT of leverage in that sensor. Sometimes the through-access sockets come in handy as anything.

That one did the trick -- easy to remove and easy to reinstall.

The pulley was another matter -- my 1/2" impact wouldn't budge it (after 22 years I didn't expect much better), but a bit of O/A persuasion did the trick.

Everything was cleaned and moved over to the new pump, and it was ready to install.

The banjo bolt received new copper washers and all the fittings were double checked for leaks.

Everything put back in order and the reservoir was refilled with fluid -- a few turns of the steering wheel left/right to bleed and refill, and we're good to go.

This old car is good for one more winter -- then (unfortunately) it will need to go to the crusher -- rust has taken it's toll and the frame is trash.