If your cutter doesn't produce a plasma arc, then it may be a lack of air pressure. Most common issue is that the air regulator on the unit is set too low. If there isn't enough air pressure the arc won't ignite. Second most common problem is an air leak in the torch itself or in the hose.

I have a cheap Chinese Plasma that I bought 11 years ago. I expected it to fail at any time, but is just kept chugging along doing its job. Well today it stopped doing its job and the torch quit lighting. I checked the normal problem areas -- air pressure, clogged head unit and nozzle, but nothing helped. I did notice that the air solenoid still worked and when it actuated the protective rubber cable cover inflated. That should not happen, so I guessed that the air hose inside the cable cover had broken. Time to take this thing apart.

First the cutting torch. These torches are a common design and are found on many other manufacturer's cutters. Three screws hold the thing together

The torch head itself -- very simple design -- only one wire needed to be de-soldered, everything else unplugged.

All the parts easily unscrew or unplug

Once the torch head was freed from the hoses and connections, the red outer sleeve was simply cut lengthwise with sharp scissors, and the inner compressed air hose and electrical wires were exposed, The red outer sleeve will be reused.

As you can see the air hose has cracked and deteriorated after a decade of use.

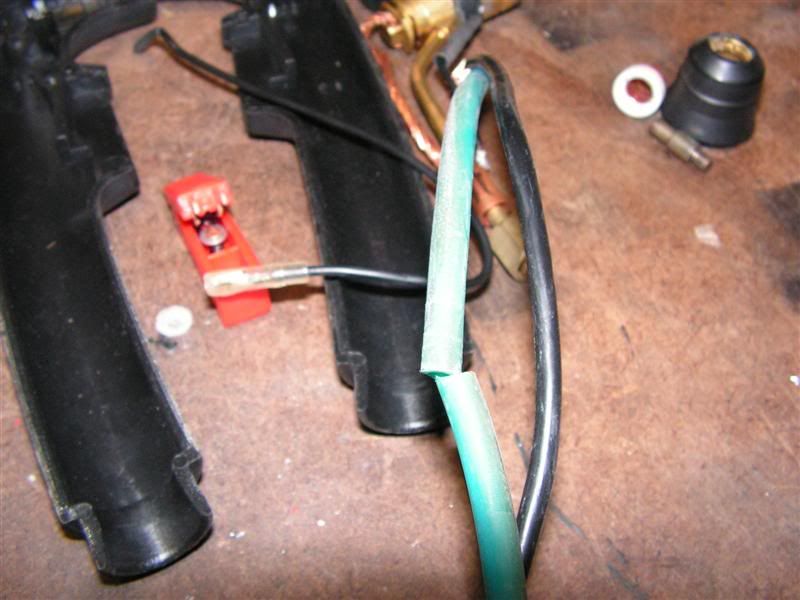

The compressed air hose was cut loose from its connector

The wires were separated as well

Now for the fix. I took some clear 1/4" plastic tubing and fit it on the OEM barbs.

The electrical connections were plugged back in place and the one wire that was desoldered before was resoldered with some shrink tubing added for protection.

All the wire bundles were stuffed back into the split red cover and electrical tape was used to wrap the cover.

This was an emergency fix for me, but a better approach would be to use a removable zippered TIG welding cable cover instead of the red cover. By using a zippered TIG cover, if there is a problem in the future, the cover can be easily unzipped to expose all the wires and hoses and maintenance will be a breeze.

Everything bundles up and plugged in -- Voila!!! We have ignition -- everything works. Total cost 2 hours of my time and $4.00 in clear 1/4" tubing

Onward -- this cutter works like new again.