91

MACHINE SHOP / Re: Engine valve and seat grinding..

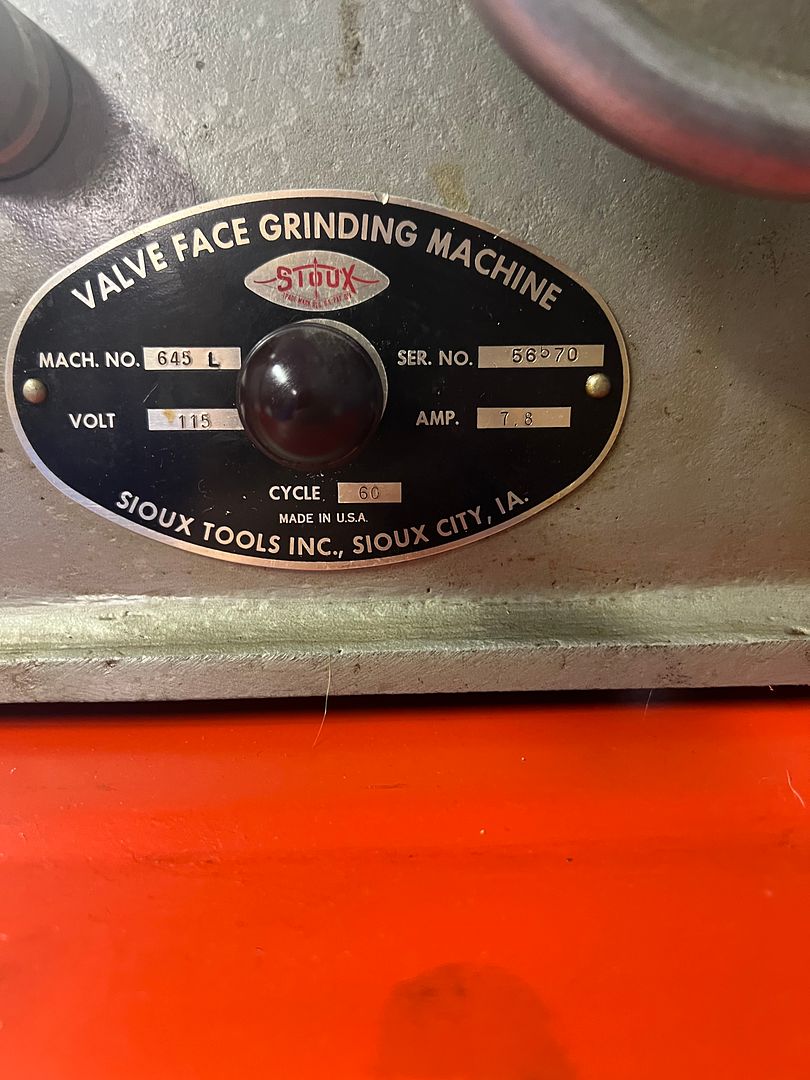

« Last post by goodfellow on April 12, 2024, 07:52:03 AM »When I had my shop, we had a Black & Decker seat grinder. I can't remember which valve grinder we had, it might have been a Sioux, but I bought it used from our local NAPA parts store machine shop. It was said to be worn out but once I cleaned it up the only thing I could find wrong was excessive play in the guides that were used in the mechanism to slide the valve back and forth across the grinding stone. My father-in-law was a tool and die maker so I asked him to take the guides to work and remove the clearance plus a little more. When I got them back, I installed with some shim stock to get the clearance just right so the table slid smoothly without any chatter when cutting the valve. That grinder served me well up until I sold the place. I wish I had a setup now as this sort of work is getting hard to get done as the automotive machine shops close up one at a time.

Lou Manglass

Same here -- B&D made a good machine, but in my humble opinion it was not as versatile as the Sioux. I learned on the B&D as a young mechanic, and about 20 ago I saw one on Craig's list for sale. Couldn't pass on it -- and the wife actually encouraged me to get it. It was a complete kit, and included a pneumatic valve seat grinder, a complete set of stones, and a nice slew of valve guide reamers. All housed in the OEM cabinet.

I posted the original link to the machine way back on GG version 1.0 -- that's quite a few years ago. Glad I saved the write-up and reposted on GG 2.0

https://garagegazette.com/index.php?topic=65.msg499#msg499

Recent Posts

Recent Posts