After taking a closer look at this thing last evening, I realized that it didn't work. At that point I pretty much decided to take it apart and refurbish the unit.

Here are some pics of what I started with.

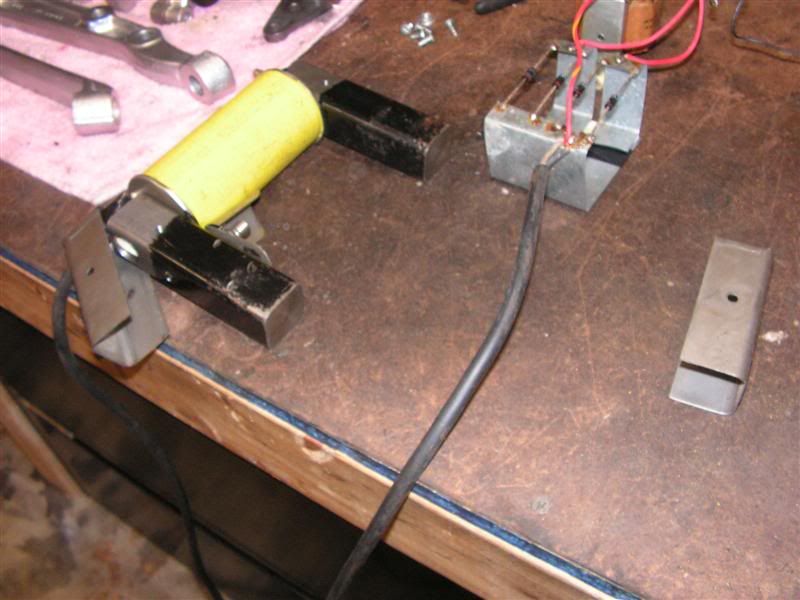

This is old technology so there is a separate power supply under that left side of tool box cover. Time to pull the cover, and "Surprise""!!! This power supply should have a tube type rectifier -- obviously somewhere along the line the old rectifier was replaced.

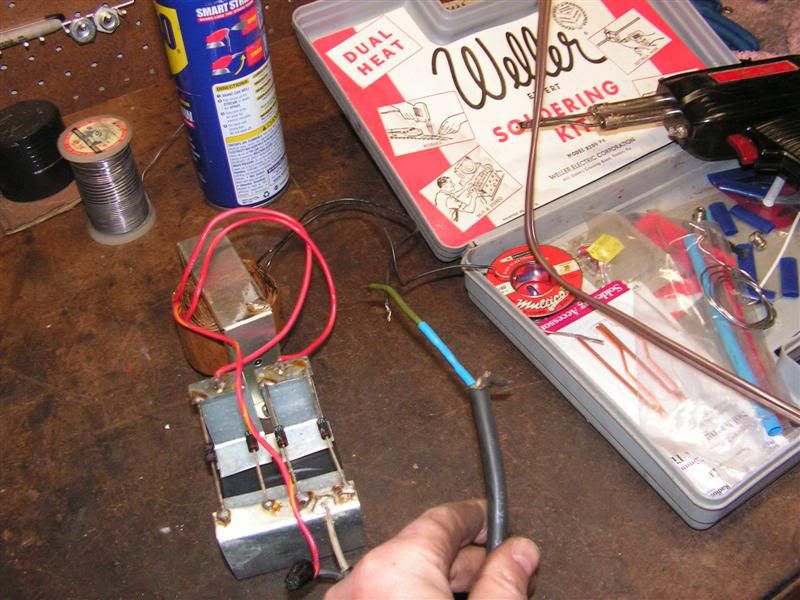

The connections are pretty shoddy as well. These will have to be soldered.

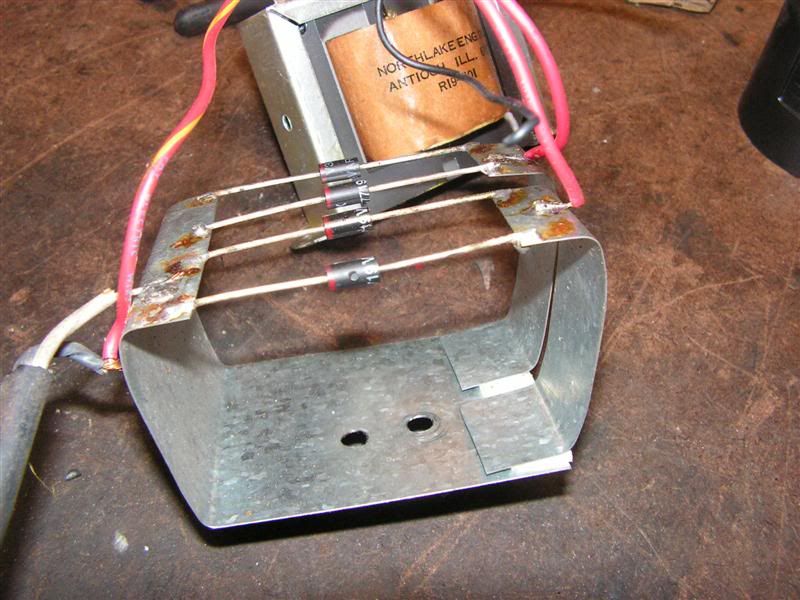

What REALLY was intersting was the "new" rectifier!! This thing is pure homemade "goodness". Look at the simplicity of this design.

The rectifier consists of three pieces of sheetmetal and four diodes. Note the double stick tape underneath the right side. This not only holds the sheetmetal in place, but also provides the insulation. I insulated this section a bit more, but everything else looked great. The diodes are simply soldered across this sheetmetal structure -- I LOVE IT!!! The transformer is also new --

The cord looked to be in good shape, but "surprise again!!" the cord ground had been cut off at some point.

With all the electronics out of the way, the tool box was cleaned stripped and painted with silver Rustoleum Hammered Paint.

While the box was drying, I resoldered the loose connections and the ground. I also disassembled the yoke handle and found a broken connection -- that's why the yoke didn't produce a magnetic field. -- No big deal!!!

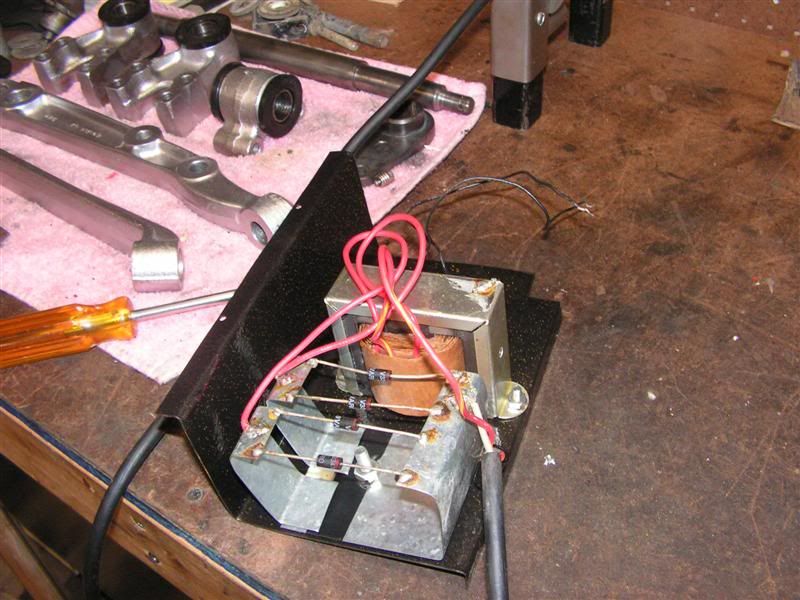

I also painted the power supply cover and reassembled the electronics with a proper ground, and installed it back in the tool box

The OEM sticker was saved and glued back in place. (Sadly, the other stickers on the outside of the box were trash and could not be saved).

The accessories were also cleaned, and in case of the metal parts; they were wire wheeled.

Overall, the entire thing looks pretty good, and it does function again.

I tested it on an old cast iron exhaust manifold -- works well!!!